Description

WalkAbout is an innovative new system from SpanSet, the global manufacturer of height safety, lifting, load restraint equipment and training to the highest standards.

The WalkAbout system is designed to be quicker, safer and cheaper than traditional access methods for many applications.

The WalkAbout system is a tensioned, walk-on deck which, when installed on a structure, will give a stable base for workers to carry out a wide range of construction and maintenance tasks. WalkAbout has been used to great success to complete roofing installations, glazing work and remedial joinery to glue laminated beams.

Tension is applied through a ratcher tensioning device which includes SpanSet’s patented Tension Force Indicator (TFI). The TFI ensures that correct pretension is applied during the Installation process, resulting in quantifiable and calculable structural loading characteristics.

The WalkAbout Access and Safety System has been designed to provide a stable, temporary working platform for working at height. Correct Installation is required to maximise the performance of the product.

The system primarily uses the following components:

WalkAbout 4m Panel

The panel comprises a mesh upper walking surface with supporting welded webbing, and a sub-structure of webbing arranged in a grid configuration which provides the main strength bearing elements. The substructure webbing grid has interconnection rings between its 4 longitudinal (orange) and 4 latitudinal (yellow) webbing straps to distribute the loading to the supporting structure. The grid also includes two auxiliary multi-panel straps (1 blue longitudinal and 1 blue latitudinal) which are only attached to the structure or to other panels as required by the nature of the installation.

The walking surface includes a ‘bias key’ which indicates the panel orientation to the installer during the WalkAbout Infill ADD Panel

To provide a continuous working platform the joint gaps between panels and structures require ‘filling’. The infill panel has been designed to bridge gaps between 4m panels and is easy to fit and secure. The infill panel features webbing loops which fit through the eyelets on the 4m panels and are then fixed into place with high strength cord. The infill panels are also designed to overlap where long sequences of the infill panel are required.

Panel Tensioning Ratchet

Available in a variety of lengths and configurations, the web tensioning ratchets are the primary means of applying and maintaining pre-tension to the sub-structure web grid. Using the SpanSet patented Tension Force Indicator (TFI), installers are able to verify correct 250daN application of pretension at the installation phase as well as during use.

Panel Connectors

An oval screw-gate connector is used to connect the various elements of the system together. The connector features a two action gate mechanism to ensure there is no accidental disengagement.

Case Studies

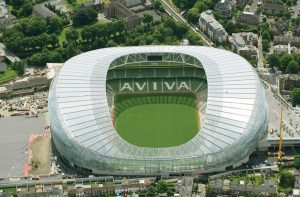

The original multi-discipline ground was in existence at the Lansdowne Road site since 1872. In its old incarnation, prior to closure in December 2006, it was the oldest rugby union ground worldwide and oldest sports stadium in Europe. The stadium is the home to the Irish national rugby and Republic of Ireland national football team. Aviva Stadium is now Ireland’s only UEFA Category 4 Elite Stadium and has won a number of awards including RIAI and RIBA. The Aviva Stadium in Dublin, built by John Sisk & Son and completed in April 2010. WalkAbout was used in the construction of the 19,000 sq.m stadium roof with 4,251 polycarbonate panels.

The original multi-discipline ground was in existence at the Lansdowne Road site since 1872. In its old incarnation, prior to closure in December 2006, it was the oldest rugby union ground worldwide and oldest sports stadium in Europe. The stadium is the home to the Irish national rugby and Republic of Ireland national football team. Aviva Stadium is now Ireland’s only UEFA Category 4 Elite Stadium and has won a number of awards including RIAI and RIBA. The Aviva Stadium in Dublin, built by John Sisk & Son and completed in April 2010. WalkAbout was used in the construction of the 19,000 sq.m stadium roof with 4,251 polycarbonate panels.

The roof construction original planed to use a scaffold structure to install the glazing bars and polycarbonate panels. At an early stage of the roof construction the WalkAbout system was trialled alongside the scaffold system to identify if time and cost savings could be made. As a result of these trials the WalkAbout system was adopted as the access method for all the roof construction. The grounds for this decision were the speed at which the system can be installed and dismantled with fewer staff. This gives major savings in both man hours worked at height and reduced cost in both labour and on hire cost.

Inanition to the direct benefits the construction also benefited from the increased access now that the scaffold structures were not in place and work could continue at ground level providing further time savings to the project. As a result of the use of WalkAbout the project saved 16 weeks construction time and completed the roof works ahead of schedule.

The Enterprise South Liverpool Academy is a sixth form college located in Garston, Liverpool. Lend Lease were the principle contractor for the project. One of the most striking features is the 40m diameter, triangular-shaped, full-height glazed atrium which dominates the interior of the new Academy. Installing the glazed roof of the atrium would normally mean a considerable amount of time and cost expended on a temporary works structure, such as a birdcage scaffolding system. However Lend Lease decided to weight up alternative solutions.

The Enterprise South Liverpool Academy is a sixth form college located in Garston, Liverpool. Lend Lease were the principle contractor for the project. One of the most striking features is the 40m diameter, triangular-shaped, full-height glazed atrium which dominates the interior of the new Academy. Installing the glazed roof of the atrium would normally mean a considerable amount of time and cost expended on a temporary works structure, such as a birdcage scaffolding system. However Lend Lease decided to weight up alternative solutions.

Jason McKnight, assistant project manager for Lend Lease with the assistance of envelope subcontractor Red Window Systems, plus WalkAbout installer Safety Net Services investigated what solutions were available in the market as an alternative to the traditional access methods. They eventually settled on WalkAbout, a work-at-height solution created by SpanSet, which acts as a safe working platform.

Use of the WalkAbout system had many benefits for the construction project. WalkAbout was much quicker and safer to install with the work being carried out from MEWPS which eliminated fall arrest. The installation time was greatly reduced; the total installation time for WalkAbout was 10 days where as for a traditional scaffold the construction time would be several weeks with more staff working at height. As a direct result of using the WalkAbout system 4 weeks were saved in erection and dismantling with a financial saving in the region of £35K.

The ETFE roof, which spans the atrium at BARTs, is now complete. A system called the SpanSet WalkAbout was used, and it is the first time that it has been used for ethylene tetrafluoroethylene (ETFE) roof installation. ETFE, the material from which the roof is constructed, is a tear resistant, long life, plastic polymer made into a thin film. Transparent windows are created by manufacturing cushions using 3 layers of the film to form cushions. The cushions are installed between lightwell steel trusses and inflated giving the roof its ‘bubble’ effect.

The ETFE roof, which spans the atrium at BARTs, is now complete. A system called the SpanSet WalkAbout was used, and it is the first time that it has been used for ethylene tetrafluoroethylene (ETFE) roof installation. ETFE, the material from which the roof is constructed, is a tear resistant, long life, plastic polymer made into a thin film. Transparent windows are created by manufacturing cushions using 3 layers of the film to form cushions. The cushions are installed between lightwell steel trusses and inflated giving the roof its ‘bubble’ effect.

This type of roof was installed at BARTs due to its light weight which allows the supporting steel to be very slender. This type of construction allows maximum light into the building through the atrium. Shading printed onto the top 2 layers of ETFE can be overlapped by changing the air pressures between the cushion layers. This allows the roof to provide either solar shading or full daylight during the day whilst minimising light ‘leaking’ from the building during the night.

Elsewhere, ETFE roof installation has been carried out from safety nets. Bill James, Steve Owens and Nick Wing visited a non-Skanska job in Wakefield to witness how the installation was carried out using nets. They decided that this method did not meet the high safety standards expected at BARTs. This led to research to find a suitable alternative method of installation. This research found an access system called the SpanSet WalkAbout.

The WalkAbout system uses a tough, flexible, non-tear fabric which is supported on tensioned webbing straps locked in place by ratchets and karabiners. The fabric panels are tied together to provide a stable working platform which allows access to large working areas at height but without the cost of a traditional birdcage scaffold.

Installation of the SpanSet system is carried out by specialist trained riggers. The system is strong enough to support both personnel and materials.

The benefits of using the SpanSet system for ETFE roof installation are clear to see:

- Quicker Installation of ETFE roof

- No material/tools can drop through it

- No need for exclusion zone beneath it

- Allows light through which benefits contractors working beneath it

- Podiums can be used on it

- Up to 8 personnel were working on it at any one time

- No stress on workers joints normally associated with installation using nets.